Effective electronics component procurement is a critical aspect of any manufacturing or product development process. Sourcing the right components at the right time and cost can significantly impact a company’s bottom line. In this blog post, we’ll explore some essential strategies to streamline your electronics component procurement process.

Supplier Relationship Building:

Building strong relationships with reliable suppliers is key to successful procurement. Establish open communication channels and regular interactions to foster trust. A good relationship can lead to favorable terms, priority access to components, and even early insights into industry trends.

Diversified Supplier Base:

Relying on a single supplier can be risky. Diversify your supplier base to mitigate potential disruptions due to shortages or unexpected issues. Multiple suppliers provide flexibility and leverage during negotiations.

Real-Time Inventory Management:

Implement an inventory management system that provides real-time visibility into component availability. This helps avoid overstocking or understocking, reducing carrying costs and production delays.

Demand Forecasting:

Accurate demand forecasting is crucial. Leverage historical data, market trends, and upcoming product launches to estimate component requirements. This enables you to plan ahead and secure components before demand spikes.

Quality Assessment and Testing:

Prioritize quality over cost. Perform due diligence on potential suppliers to ensure they meet quality standards. Regularly test components to identify counterfeit or substandard parts, preventing production issues down the line.

Risk Management:

Assess and mitigate potential risks in the supply chain. Develop contingency plans for scenarios such as supply disruptions, geopolitical issues, or natural disasters. Being prepared can help minimize the impact on production.

Negotiation Strategies:

Effective negotiation can lead to cost savings. Research market prices, analyze supplier offers, and negotiate for better terms, bulk discounts, or extended payment terms.

Lifecycle Management:

Electronics components have finite lifecycles. Stay informed about component obsolescence and end-of-life announcements. Plan for suitable replacements or stock up on critical components before they become unavailable.

Collaboration with Engineering Teams:

Close collaboration between procurement and engineering teams is essential. Involve engineering early in the procurement process to identify suitable alternatives and avoid last-minute changes that could disrupt the supply chain.

Continuous Monitoring and Improvement:

Regularly review and analyze your procurement process for areas of improvement. Embrace new technologies and methodologies that enhance efficiency and reduce procurement lead times.

Conclusion:

Efficient electronics component procurement requires a combination of strategic planning, relationship building, and continuous improvement. By implementing these strategies, you can optimize your procurement process, minimize risks, and contribute to the overall success of your projects and business.

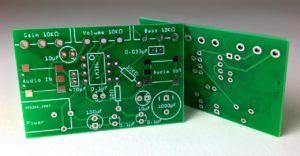

PC: Mr.Prashanth, Procurement Manager, RioSH Technologies